In the world of modern manufacturing, precision and efficiency are paramount. For enterprises seeking to create high-quality custom parts with intricate designs, the process of aluminum low pressure die casting has emerged as a game-changer. This innovative technique allows for the creation of a diverse range of components, from auto parts to heavy truck components, with unparalleled accuracy and consistency.

Aluminum low pressure die casting is a sophisticated manufacturing process that combines state-of-the-art technology with skilled craftsmanship. It involves the creation of intricate molds, the precise pouring of molten aluminum, and the extraction of meticulously detailed finished parts. This process offers several distinct advantages that make it the method of choice for industries demanding excellence in every piece.

Automotive components, such as swash plates, planetary plates, and exhaust cover plates, require a delicate balance of strength, durability, and precision. Aluminum low pressure die casting meets these demands flawlessly. The process allows for the creation of intricate designs that contribute to optimal performance. Whether it's a swash plate that ensures the smooth movement of vehicle parts or a planetary plate that enables controlled power distribution, the accuracy of low pressure die casting guarantees reliable functionality.

The structural integrity of bridges depends on the quality of their components. SS/A stand columns and pillar heads are crucial elements that demand utmost precision in manufacturing. Aluminum low pressure die casting provides the ideal solution by producing parts with consistent material properties and exceptional dimensional accuracy. These components, subjected to heavy loads and environmental stressors, benefit from the durability and reliability inherent in the low pressure die casting process.

Heavy trucks operate under challenging conditions, necessitating components that can endure stress and wear. Central filter housings and cleaning windows are essential for the proper functioning of these vehicles. Aluminum low pressure die casting creates parts with a fine balance of strength and weight, ensuring longevity without compromising performance. The process allows for complex geometries that facilitate efficient assembly and operation, contributing to the overall reliability of heavy trucks.

In industries where safety and precision are non-negotiable, such as gas distribution, DN series valves and flanges play a critical role. These components require intricate designs to maintain accurate control over gas flow. Aluminum low pressure die casting delivers the necessary intricacy, allowing for the creation of parts with tight tolerances and consistent dimensions. The result is gas valve components that meet the highest standards of reliability and performance.

Creating custom parts through aluminum low pressure die casting is not just a technical feat; it's a collaborative endeavor. The success of this manufacturing method hinges on the synergy between professional mold design, meticulous mold manufacturing, and precise die casting production. Enterprises integrating these phases seamlessly ensure that the end product meets and exceeds expectations.

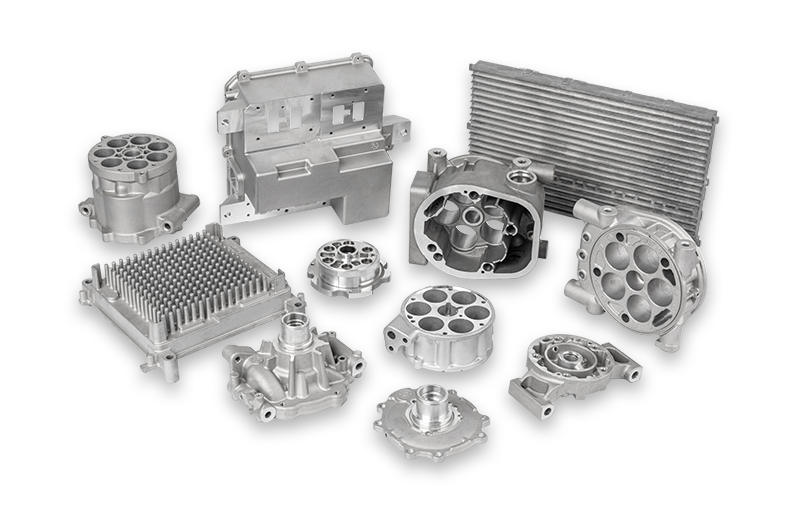

Aluminum low pressure die casting isn't just a technique—it's an embodiment of your commitment to excellence. Nbzunhang adopt Aluminum Low Pressure Die-Casting to manufacture type of Auto Parts (Swash Plate, Planetary Plate, Exhaust Cover Plate), Bridge Members (SS/A Stand Column, Pillar Head), Heavy Truck Parts (Central Filter Housing, Cleaning Window) · Gas Valve (DN Series Valve & Flange).